System and method of UVC LED water disinfection

发布时间:2021-09-23 14:17

来源:萤光创新

Ultraviolet has become a star in the disinfection industry. It is increasingly used in critical applications that require alternative disinfection options. UV disinfection has several advantages, including:

1. Chemical free UV can provide physical therapy without the use of harmful chemicals, no DBP, and no risk of harmful disinfection by-products from chemical treatment.

2. Effective pathogen inactivation UV is very effective against a variety of water-borne pathogens, including chlorine resistant organisms such as Cryptosporidium and Giardia.

3. Low maintenance Rugged technology is easy to use and maintain. Historically, traditional gas discharge (mercury) lamps have been used in water treatment systems to emit ultraviolet rays.

Recently, a new light source (UV LED) emitting in the sterilization wavelength range (250 to 285 nm) has been rapidly developed and applied to small flow water treatment systems. In addition to the core advantages of UV disinfection technology listed above, UVC LED has other advantages, including:

1. Mercury free Traditional UV lamps contain mercury, but UV LEDs do not contain harmful substances, thus eliminating the risk of mercury overflow due to lamp tube damage.

2. Small floor area Compared with traditional UV system, high power density UVC led and advanced control can achieve smaller floor area.

3. Instant on / off The system is friendly to intermittent flow and can be turned on and off immediately without any preheating time requirements, which also enhances the energy-saving effect and prolongs the service life of the lamp.

4. Infinite cycle The lamp life is not affected by the on / off cycle, and unlimited cycles are allowed.

5. Temperature independent The LED does not transfer heat to the water, so regardless of the water temperature, it can limit lamp pollution and ensure a constant UV output.

At a higher level, LEDs provide the same physical disinfection safety as mercury lamps. However, it is important to check the fundamental difference between UVC led and mercury lamp. New thinking and design methods are needed to make full use of the potential of this exciting new light source, and an overall system method is needed to make full use of the great potential provided by UVC led. The following are the key engineering issues related to the development of UVC led system:

Nature, robustness and reliability of light source

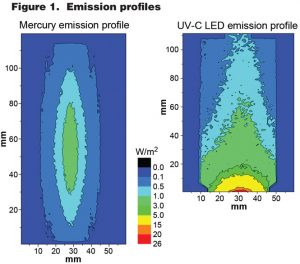

The main design challenge is to understand that completely different light sources have slightly different sterilization wavelengths. Attention must be paid to fully characterize its robustness and reliability. A key to laying the foundation for this design transformation is the difference in emission curves between the two lamps (Fig. 1). From this figure alone, it is easy to see the need to change the geometry of the UV reactor design. Mercury lamp needs cylindrical design, while UVC LED has light source emission curve, which can be used but does not need cylindrical contour. In addition to having fundamentally different emission curves, the spectral output of UVC LEDs must also be checked. With the popularity of low-pressure mercury lamps, 254 nm has been considered as an ideal wavelength. Although the peak bactericidal efficiency is between 260 and 270 nm, it still depends on the specific pathogen. UVC LEDs are quasi monochromatic (most of the output falls within a 10 nm gap), but can be designed for various wavelengths in the sterilization range to target specific pathogens or general peak pathogen UV sensitivity. (e.g., 255, 265, 275 nm, etc.). The choice of wavelength by the designer usually depends on the combination of cost, life, target pathogen and UV intensity output. In addition, due to the lack of experience in using this new innovative light source, manufacturers must conduct extensive pre-test on UVC LEDs in order to be confident in the durability and emission time of these devices. UVC led measurement and test equipment is very important for generating these important data.

Reactor design

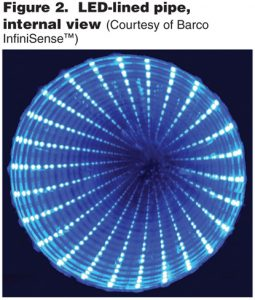

The main design challenge is to improve the overall system efficiency by designing an efficient UV reactor. Due to the difference of lamp emission curve, the treatment room using LED may be very different from that using traditional mercury lamp. Designers must find a way to effectively distribute this new light source in the reaction chamber. Currently, the output power of commercial UVC LEDs is less than 100 MW (about 3.5 mm for a single device) 2) Compared with 17 watt low-pressure mercury lamps (about 350 mm x 15 mm). Although a single UVC LED is not as powerful as a single mercury lamp, their UVC output and power density (output per unit area) It has increased exponentially over the past few years. Therefore, more efforts must be made to design efficient UV reactors to compensate for and maintain the overall efficiency of the water treatment system. Some designs may be elegant, such as LED lining of pipes (as shown in Figure 2) However, the overall efficiency must be the driving premise. Once the UVC LED technology is mature to the level of visible LED technology and is very efficient, they can be placed in almost any configuration; however, at present, the UVC led system can be effective only when it is built around the extremely efficient reactor design. At present, only a few UVC led processing systems are available, and each system has different reaction conditions In response to reactor design, efficient reactor design is not easy to find, and the development team spent years designing and verifying new reactor configurations that are more efficient than mercury lamp based systems. Advanced modeling tools, such as computational fluid dynamics and finite element analysis, are deployed with physical measurement technologies such as biological dosimetry and photometer.

Thermal management

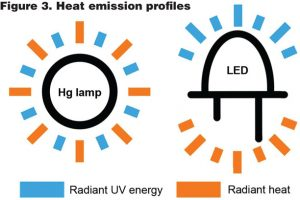

The main design challenge is to manage the heat emitted by UVC LEDs to ensure long lamp life. One of the main advantages of LED based systems is that they do not transfer heat to water (Figure 3) For example, LEDs emit all light on the front surface of the equipment and heat on the rear surface, while Mercury Lamps emit light and heat through the same surface; UVC LEDs emit more heat than mercury based lamps, which must be properly managed. This can be done in many ways and will help prolong the service life of the system. New skills or experts are required to effectively complete this task If the LED is kept at a high temperature, the UV output of the LED will be reduced, and the disinfection efficiency of the system will be reduced over time. The implementation of heat reduction technology and heat monitoring is the key to maintaining long-term UV LED. According to the service situation, the replacement interval of these lamps can be several years compared with the annual replacement requirements of traditional mercury lamps.

System monitoring / troubleshooting

The main design challenge is to understand the key parameters affecting the life and performance of UVC led and effectively monitor them. Real time monitoring of disinfection performance and alarm indication is very important for an effective UVC led system. It is important to know not only which indicators to track, but also how to implement them, which is very important to ensure system confidence. Intelligent design includes monitoring the health of lights and Which checkpoints require error indicators, alarms, and system shutdown protocols. This tracking provides end users with the tools they need to ensure that appropriate indicators are met and that their systems are at the required inactivation level and life expectancy.

The introduction of UVC LED light source into the water disinfection industry poses a challenge to designers and users to change their views on ultraviolet disinfection. Although some design principles previously used for mercury lamps are combined, in many cases, a transformation is needed to transition from analog disinfection to digital disinfection. Compared with focusing on the efficiency of lamps, it is more important to focus on the overall system efficiency, which depends on the overall system efficiency It depends on lamp efficiency and reactor efficiency. Therefore, when the world is waiting for UVC led to become more efficient, reactor design becomes the decisive factor of system efficiency. The efficiency of mercury lamp is moderate, and the efficiency of tubular geometry reactor is also moderate. At present, the efficiency of UVC LED light source is low, so it must be used together with highly efficient reactor to make the efficiency of the system reach or exceed Efficiency of mercury based water treatment system.

conclusion

Many designers soon learned that traditional UV reactors for mercury lamps are not suitable for LED driven systems. Fluid dynamics requires highly advanced reactors to achieve consistent and effective effects. With the rapid development of UVC LEDs, the efficiency of LEDs will increase and the price will decrease. Therefore, UVC LEDs will eventually be widely used without paying attention to reactor efficiency. However, In the foreseeable future, when choosing to deploy UVC LED equipment, the overall system design is very important. Users, regulators and water system designers need to be aware of this and understand what is needed to build and evaluate efficient sterilizers, because as we know, not all sterilizers have the same effect.

Qingdao fluorescent Innovation Technology Co., Ltd. has a professional postdoctoral team, focusing on the research of ultraviolet sterilization application. After years of deep cultivation in the ultraviolet industry, the company has obtained a number of national invention and utility model patents. At present, a number of sterilization module products have been put into the market. For more details, please visit the company's website www.qdyingguang.com, contact the company or pay attention to wechat official account

Article key words: UVC, UVC led, deep UV, UV sterilization, deep UV LED